Key Considerations in HTST Pasteurization

Comments Off on Key Considerations in HTST PasteurizationCommonly referred to as the “continuous method” or flash pasteurization, high-temperature short-time (HTST) pasteurization reduces the bacterial content in dairy products and other viscous liquids. This destroys dangerous organisms — such as bacteria, viruses, protozoa, molds, and yeasts — that may be present during the production of milk and milk products.

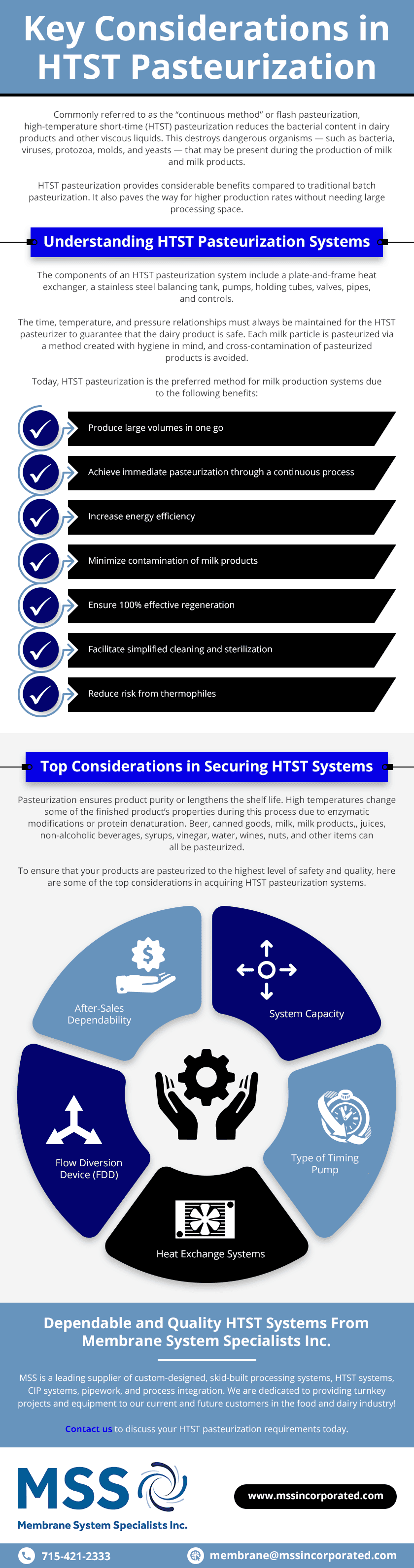

HTST pasteurization provides considerable benefits compared to traditional batch pasteurization. It also paves the way for higher production rates without needing large processing space.

Understanding HTST Pasteurization Systems

The components of an HTST pasteurization system include a plate-and-frame heat exchanger, a stainless steel balancing tank, pumps, holding tubes, valves, pipes, and controls.

The time, temperature, and pressure relationships must always be maintained for the HTST pasteurizer to guarantee that the dairy product is safe. Each milk particle is pasteurized via a method created with hygiene in mind, and cross-contamination of pasteurized products is avoided.

Today, HTST pasteurization is the preferred method for milk production systems due to the following benefits:

- Produce large volumes in one go

- Achieve immediate pasteurization through a continuous process

- Increase energy efficiency

- Minimize contamination of milk products

- Ensure 100% effective regeneration

- Facilitate simplified cleaning and sterilization

- Reduce risk from thermophiles

Top Considerations in Securing HTST Systems

Pasteurization ensures product purity or lengthens the shelf life. High temperatures change some of the finished product’s properties during this process due to enzymatic modifications or protein denaturation. Beer, canned goods, milk, milk products,, juices, non-alcoholic beverages, syrups, vinegar, water, wines, nuts, and other items can all be pasteurized.

To ensure that your products are pasteurized to the highest level of safety and quality, here are some of the top considerations in acquiring HTST pasteurization systems.

System Capacity

It is critical to determine the capacity requirement of your pasteurization system. This will allow you to arrive at an assembly design ideal for your plant size, layout, and production demands. It will also provide the most efficient overhead and operational cost for your production.

A seasoned HTST pasteurization system supplier can easily help you find the most cost-effective assembly size to fit your needs.

Type of Timing Pump

The timing pump controls flow rates within the HTST pasteurization system. This portion draws the raw substance from the generator and pushes it forward to undergo the process.

A skilled HTST pasteurization system manufacturer can automate this part to set the maximum delivery rate equal to or less than the calculated maximum flow rate to achieve minimum holding time in every batch production.

Heat Exchange Systems

There are two types of heat exchange systems for HTST systems. First, the Plate Heat Exchanger or PHE transfers heat from the pasteurized product to the raw product. The second type is the Tubular Heat Exchanger (THE), with no contact points in the product channel. The PHE type is more efficient than THE HTSTs.

Flow Diversion Device (FDD)

The flow diversion device’s function is to precisely and safely control the flow of raw and pasteurized products. It controls the pump and other valves and lets the product flow forward when the minimum temperature is met.

After-Sales Dependability

To ensure the quality of products produced by HTST pasteurization systems, working with a machine provider with excellent aftersales service is important. Purchasing a system for your production requires regular maintenance. Thus, it would be best to acquire your equipment from companies you can rely on for quality servicing.

Dependable and Quality HTST Systems From Membrane System Specialists Inc.

MSS is a leading supplier of custom-designed, skid-built processing systems, HTST systems, CIP systems, pipework, and process integration. We are dedicated to providing turnkey projects and equipment to our current and future customers in the food and dairy industry!

Contact us to discuss your HTST pasteurization requirements today.