Whole Milk

Preconcentration Ahead of Cheese Production

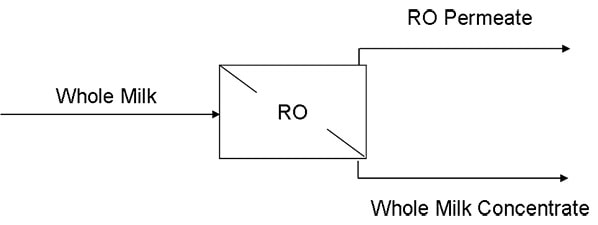

Whole milk can be concentrated with Reverse Osmosis (RO) to levels of 25-30% total solids (TS). This represents a 2-2.5x volume concentration factor (VCF).

RO refers to a pressure driven membrane separation technique in which a membrane is employed to separate different components in a fluid mixture. RO membranes have pore sizes less than 0.001 micron. Separation occurs based on molecular size and chemical interactions between the membrane and fluid components that are in contact with the membrane. In this process, pressure is used to push water molecules through the pores of a membrane while retaining the colloidal solids and salts. Typical operating pressures range from 450-600 psi.

Permeate quality from RO systems depends on the quality and composition of the feed and the level of concentration. The higher the TS, the greater the amount of constituents in the permeate. Typically, RO permeate will contain small (but measurable) amounts of organic solids. The process performance is greatly affected by operating parameters such as feed flow rate, pressure, temperature, pH, micro-biological quality of feed stream, feed concentration, and fouling characteristics of the membrane for various components.

Reverse Osmosis, which avoids the phase change seen with evaporation, preserves the functionality of proteins and the product does not have a cooked flavor. Processing temperature of whole milk is typically ~45°F. Systems are properly designed and operated to maintain the integrity of the fat molecules. Doing so prevents the rancidity caused by damaged or ruptured fat molecules.

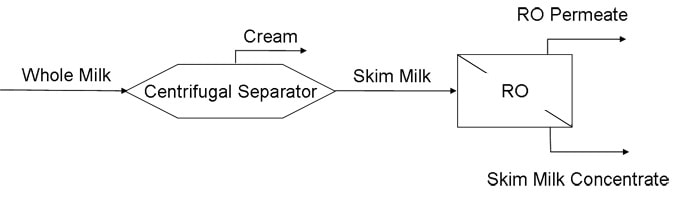

Skim Milk

Buttermilk concentration by cold reverse osmosis (RO) is frequently used as an efficient and economical way to increase capacity of a skim milk evaporation operation. MSS’ cold milk experience has shown it technically feasible to pre-concentrate raw cold (45°F) whole milk without fat damage, excessive fouling, or any rancidity. By locating the cold RO ahead of the existing HTST/separator, the existing equipment does not need to be revised. Up to 25% increase in plant capacity can be achieved with the addition of a cold whole milk RO without increasing separator or pasteurizer capacity. Although the cost for a cold whole milk RO is somewhat higher that a warm skim RO, the savings by not increasing the pasteurizer and not adding to the separation capacity results in an overall lower investment. Generally, membranes operated colder at lower concentration last longer. The cold RO permeate can effectively be utilized for cream pre-cooling or other energy saving applications.

Permeate quality from RO systems depends on the quality and composition of the feed and the level of concentration. The higher the TS, the greater the amount of constituents in the permeate. Typically, RO permeate will contain small (but measurable) amounts of organic solids. The process performance is greatly affected by operating parameters such as feed flow rate, pressure, temperature, pH and micro-biological quality of feed stream, feed concentration and fouling characteristics of the membrane for various components.

Reverse Osmosis, which avoids the phase change seen with evaporation, preserves the functionality of proteins and the product does not have a cooked flavor. Processing temperatures of skim milk are typically < 45°F or ~120°F. Skim milk can be concentrated for several reasons: reduced volume for transportation, increased production capacities, or increased TS for use in fortification. Cream skimmed from the milk prior to concentration with RO can be added to the concentrated skim in order to obtain “concentrated whole milk”.

Whey

Sweet/Acid Whey

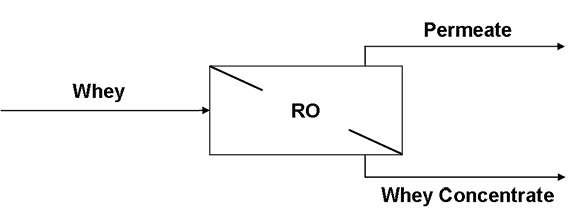

Whey concentration by reverse osmosis (RO) is frequently used to reduce volumes and increase solids content prior to transportation or further processing. RO refers to a pressure-driven membrane separation technique in which a membrane is employed to separate different components in a fluid mixture. A Reverse Osmosis membrane has pore sizes less than 0.001 micron and separation occurs based on molecular size and chemical interactions between the membrane and fluid components that are in contact with the membrane. In this process, pressure is used to push water molecules through the pores of a membrane while retaining the colloidal solids and salts. Typical operating pressures range from 450-600 psi.

Preconcentration of sweet whey before evaporation allows for more energy efficient removal of water at lower solids and increased capacity of existing evaporators. Total solids (TS) levels of 10-25% can be obtained in an efficient, practical manner. Reverse Osmosis membranes are used to remove water and will not alter the relative composition of the sweet whey components. Permeate quality from RO systems depends on the quality and composition of the feed and the level of concentration. The higher the TS, the greater the amount of constituents in the permeate. Typically, RO permeate will contain small (but measurable) amounts of organic solids. The process performance is greatly affected by operating parameters such as feed flow rate, pressure, temperature, pH and micro-biological quality of feed stream, feed concentration and fouling characteristics of the membrane for various components.

Other

Rinse Recovery

Reclaiming water from condensate, rinsing operations, and low-solid effluents allows you to find hidden value from your process and waste streams. RO technology will allow you to recover up to 90% of the volume of waste waters that would be lost through discharge. Water recovery benefits you buy: lowering water costs, reducing energy costs, decreasing raw water treatment costs, reusing valuable resources, and compliance with regulatory standards.

WPC Concentration

A combination of RO and NF can be used to concentrate whey product streams. Through these system applications levels of 30-40% TS are obtainable. These applications allow UF operation at lower solids for better efficiency and higher protein yield. These processes improve drying operations by lowering energy consumption and improving bulk density.

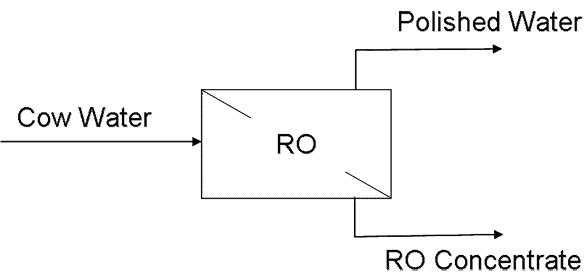

Polishing of Cow Water (Evaporator Condensate Polishing and RO Permeate)

Water recovered from processes such as evaporation or membrane processing can be subsequently handled and treated in such a manner that it can be considered a safe water supply (“acceptable process water”). Acceptable process water is suitable for intermixing with products for human consumption in certain specified applications.

Criteria for acceptable process water are detailed in USDA-Dairy Division item 113 and 115.

Reverse osmosis (RO) polishing of the streams can produce water that can be used directly for washing applications excluding final rinses of processing equipment. Polisher permeate can be further conditioned to meet potable water standards. Potable water, which may be used for final rinses, must meet the following standards:

Maximum Chemical Oxygen Demand 12 mg/l (ppm)

Mechanisms must be in place to assure that the permeate is maintained at or below these levels. Approved chemicals, such as chlorine, with a suitable retention period may be used to suppress the development of bacteriological growth and maintain a COD value of less than 12 ppm. The addition of chemicals shall be by an automatic proportioning device prior to the water entering the storage tank to assure satisfactory quality water.

State regulatory agencies will require submission of paperwork for the process water. Paperwork includes but is not limited to; a flow schematic of intended distribution, intended uses and application, and consent to perform the required tests of water quality.

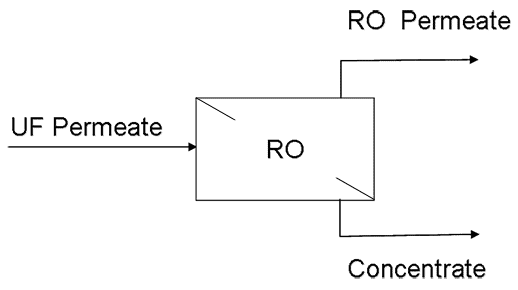

Concentration of UF Permeate

Permeate from the ultrafiltration of whey is a stream that is low in total solids (TS), typically 3.5 – 5.5% TS. UF permeate is usually 75-85% lactose on a dry basis, and is utilized for harvesting lactose or as cattle feed. Removal of water from this stream prior to further processing or transporting is essential to the economic feasibility. Membranes can be used to effectively increase the solids levels to 15% to 25%. Temperature and pH are critical factors determining the final concentration level. Due to the concentration of salts and sugars, UF permeate has osmotic pressure much higher than most other dairy streams.

At concentration >20% TS, nanofiltration membranes are occasionally used. Nanofiltration membranes will negate the effect of increasing osmotic pressure found at these TS levels. The volumes of permeate required to increase the TS levels in this range are quite small. Permeate from nanofiltration membranes at this point in a system tends to be higher in organic material.