As an industry-leading provider of equipment to the dairy and food processing industries, at Membrane System Specialists, Inc., we are capable of designing and manufacturing custom fluid separation systems for a variety of applications. Fluid separation systems remove suspended particles, microorganisms, fats, proteins, or carbohydrates from raw milk or other feedstock streams. Different membranes are used to effectively remove each type of particle based on its size. The systems we produce are capable of removing particles from as large as 10 microns to less than 0.001 microns.

The first step of the design process is a complete characterization of the customer’s feedstock and desired final product. Given the specific feedstock volume and composition, a separation system is designed with the necessary microfiltration, ultrafiltration, reverse osmosis, or nanofiltration system to create the needed streams for further processing. All equipment is manufactured to the highest quality and sanitation standards using durable materials that are easy to clean and require minimal maintenance. During the design process, our engineers are able to rapidly respond to any changes that may occur as a result of a customer request. The controls and mechanical components we use are of the highest quality in the industry and are specifically selected for their ability to endure harsh operating environments.

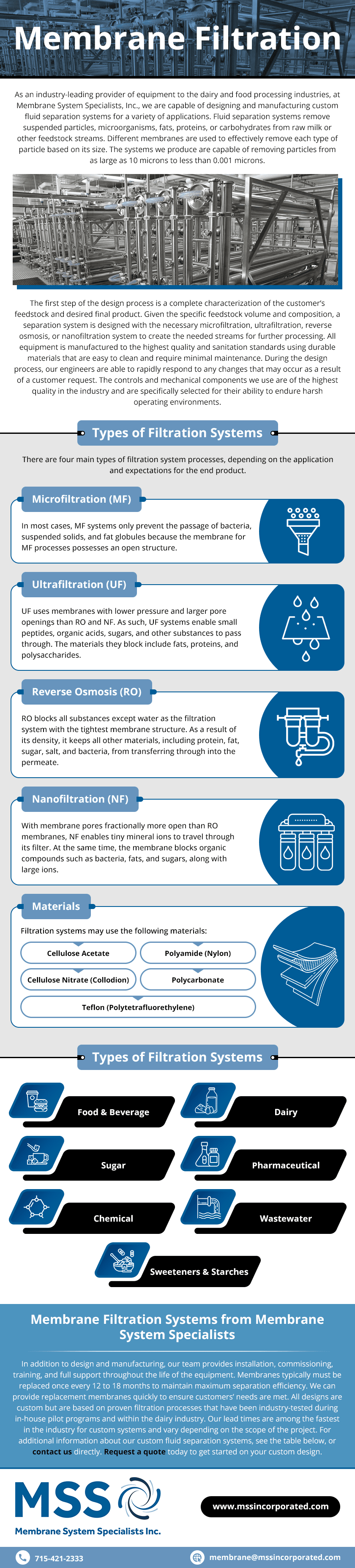

Types of Filtration Systems

There are four main types of filtration system processes, depending on the application and expectations for the end product.

Microfiltration (MF)

In most cases, MF systems only prevent the passage of bacteria, suspended solids, and fat globules because the membrane for MF processes possesses an open structure.

Ultrafiltration (UF)

UF uses membranes with lower pressure and larger pore openings than RO and NF. As such, UF systems enable small peptides, organic acids, sugars, and other substances to pass through. The materials they block include fats, proteins, and polysaccharides.

Reverse Osmosis (RO)

RO blocks all substances except water as the filtration system with the tightest membrane structure. As a result of its density, it keeps all other materials, including protein, fat, sugar, salt, and bacteria, from transferring through into the permeate.

Nanofiltration (NF)

With membrane pores fractionally more open than RO membranes, NF enables tiny mineral ions to travel through its filter. At the same time, the membrane blocks organic compounds such as bacteria, fats, and sugars, along with large ions.

Materials

Filtration systems may use the following materials:

- Cellulose acetate. This material features high strength, the capability for sterilization, and heat resistance at temperatures of up to 180° C. It has minimal ability for protein binding.

- Teflon (Polytetrafluorethylene). Teflon filters are made up of microscopic pores in the billions to form a 3D spiderweb configuration. This material is suitable for applications in need of water-resistant and non-stick filters to block particulate on the surface of a membrane.

- Polyamide (Nylon). This hydrophilic material features high resistance to solvents, making it ideal for filtering organic solvents and water. Its larger pores also allow it to isolate bacteria, roundworms, and other multicellular contaminants.

- Cellulose nitrate (Collodion). Cellulose nitrate comes in various material compositions and pore sizes that enable it to manage microbial growth. Its versatility lends its use to sterile membrane filters.

- Polycarbonate. Membrane filters may consist of polycarbonate in optical or electron microscopy applications because of this material’s porous structure and clear, smooth surface.

Industries & Applications

Many industries use membrane filtration systems for their applications, including:

- Food and beverage. As just one example of filtration for this industry, beer membrane filtration systems help filter beer during the brewing process to provide consistent output of a tastier beverage.

- Dairy. Dairy product manufacturing processes often rely on membrane filtration for products such as milk and whey.

- Sugar. Membrane filtration helps clarify unprocessed juice while eliminating the need for primary clarifiers, which helps supplement traditional filtration methods.

- Sweeteners and starches. Membrane filtration helps improve the performance of sweetener and starch products in several ways, including fructose and dextrose clarification, dextrose enrichment, and more.

- Pharmaceutical. Fermentation processes for pharmaceutical products like antibiotics use membrane filtration to recover biomass or harvest cells. Sterilization, diagnostic procedures, and more also use filtration.

- Chemical. Pigments, dyes, and other chemicals rely on membrane filtration for concentrating minerals, diafiltration, desalination, and purification.

- Wastewater. Water purification systems use membrane filters to remove harmful microorganisms and particulate from wastewater.

Membrane Filtration Systems from Membrane System Specialists

In addition to design and manufacturing, our team provides installation, commissioning, training, and full support throughout the life of the equipment. Membranes typically must be replaced once every 12 to 18 months to maintain maximum separation efficiency. We can provide replacement membranes quickly to ensure customers’ needs are met. All designs are custom but are based on proven filtration processes that have been industry-tested during in-house pilot programs and within the dairy industry. Our lead times are among the fastest in the industry for custom systems and vary depending on the scope of the project. For additional information about our custom fluid separation systems, see the table below, or contact us directly. Request a quote today to get started on your custom design.