De-salting Whey with DiafiltrationWhey

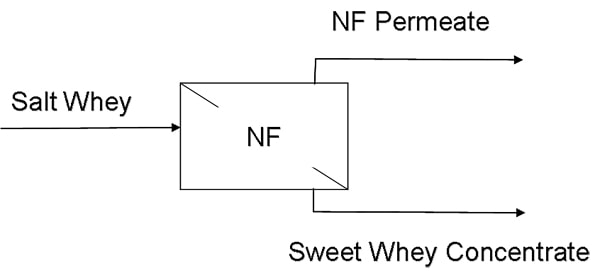

Salt whey is the final whey generated while making cheese, and is high in salt and often high in fat content. This salty whey can be collected, temperature adjusted, and processed with membrane equipment to yield a “desalted” whey stream and a low BOD, high salt discharge stream. The published regulations that apply are summarized as follows. Promptly after collection in a sanitary manner, the salty whey must be heated to 125°F (minimum) or cooled to 45°F (maximum) and stored at that temperature until it is processed by the membrane system. The maximum age of salty whey before membrane processing shall be 60 hours, calculated from the time the first salty whey in the batch is produced until start-up of membrane processing of the batch. Processing includes a diafiltration step using potable water to “wash” additional levels of the salt from the whey solids into the permeate. The salty whey shall be membrane processed and diafiltered at 125°F minimum temperature. The processing time in the membrane equipment shall not exceed 18 hours. The FDA definition of dry whey specifies that its ash content range is 7-14%. The membrane desalting process must be continued until the retentate ash content (dry basis) is reduced into the 7-14% range. After being processed according to published USDA guidelines, the recovered whey solids may be added to whey or whey products for further processing for human food. The fat can be removed from the whey solids with centrifugal separation prior to or just after being processed in the nanofiltration system.

Nanofiltration refers to a membrane separation technique in which a membrane is employed to separate different components in a fluid mixture. A nanofiltration membrane has pore sizes in the range of 0.001-0.01 micron and separates based on molecular size and chemical interactions between the membrane and fluid components that are in contact with it. A nanofiltration membrane will permit the permeation of monovalent salts (i.e. NaCl), but will retain divalent salts (i.e. CaCl2), sugars, proteins, and other higher molecular weight components. In this process, pressure is used to push the relatively smaller molecules through the pores of the membrane. The operating pressures typically range between 400-450psi for processing.

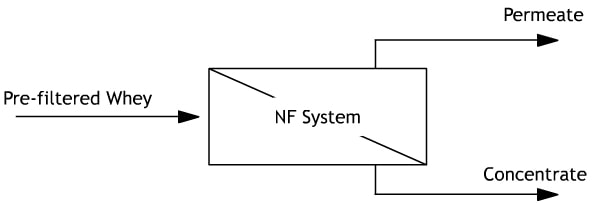

Mineral Reduction of Whey

- Low rejection of monovalent salts.

- Diafiltration can be used during processing.

- Typical reduction levels up to 30-40%.

- Reduced effects of osmotic pressure.

- System construction similar to RO.

Acid Reduction

| Parameter | Whey | NF Concentrate | NF Permeate |

|---|---|---|---|

| Total Solids | 3 – 6% TS | 18 – 25% TS | — |

| pH | 4.2 – 4.5 | 4.2 – 4.5 | — |

| DBO | — | — | 1,500 – 2,500 mg/l |

Other

Concentration of Blood Plasma

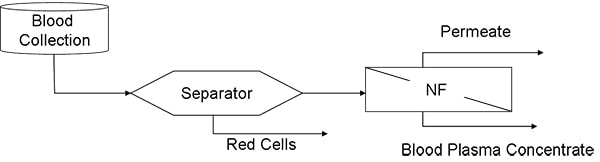

Porcine and bovine bloods can be collected and processed to generate product streams. Red blood is centrifuged with mechanical separators, yielding a 50/50 split of red cells and plasma. The red cells are usually made into blood meal. The plasma, which is very high in protein (65-75% db), can be dried and used as high-grade animal feeds. Nanofiltration systems are used to concentrate, and slightly desalt, the raw plasma from its native 7-10% total solids (TS) into product at 20-28% TS. Nanofiltration membranes allow some passage of salt, thereby permitting higher concentrations without the corresponding effect of osmotic pressure. Permeate from the nanofiltration system will be <1% TS, containing mostly salts and other small molecules.

During collection of the blood, sodium citrate is introduced. The citrate spray minimizes the coagulation of the blood and plasma streams. The blood is separated at collection temperatures, while processing of plasma is typically done at 75-85°F. The concentrated product is promptly cooled to <45°F. The raw plasma and concentrated products are perishable and must be handled accordingly.