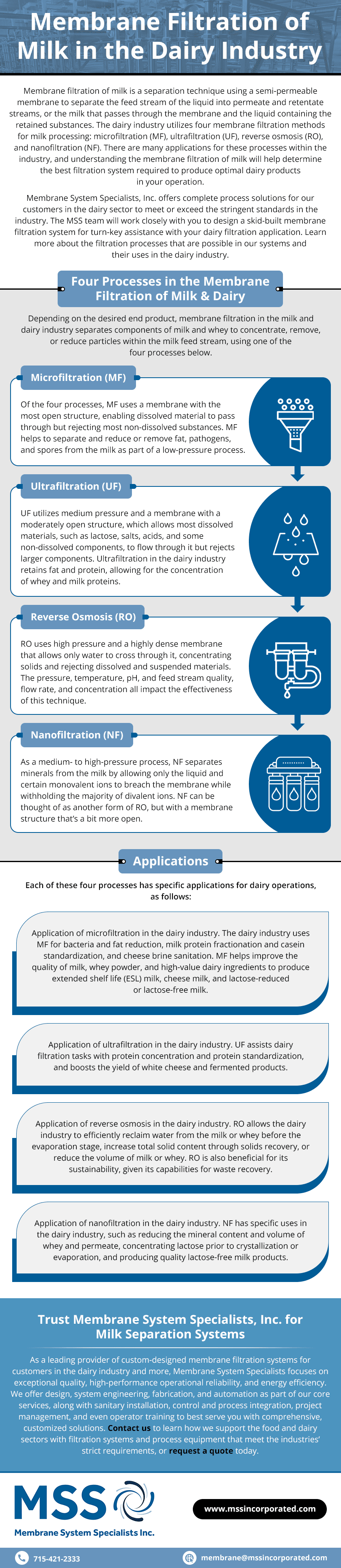

Membrane filtration of milk is a separation technique using a semi-permeable membrane to separate the feed stream of the liquid into permeate and retentate streams, or the milk that passes through the membrane and the liquid containing the retained substances. The dairy industry utilizes four membrane filtration methods for milk processing: microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), and nanofiltration (NF). There are many applications for these processes within the industry, and understanding the membrane filtration of milk will help determine the best filtration system required to produce optimal dairy products in your operation.

Membrane System Specialists, Inc. offers complete process solutions for our customers in the dairy sector to meet or exceed the stringent standards in the industry. The MSS team will work closely with you to design a skid-built membrane filtration system for turn-key assistance with your dairy filtration application. Learn more about the filtration processes that are possible in our systems and their uses in the dairy industry.

Four Processes in the Membrane Filtration of Milk & Dairy

Depending on the desired end product, membrane filtration in the milk and dairy industry separates components of milk and whey to concentrate, remove, or reduce particles within the milk feed stream, using one of the four processes below.

Microfiltration (MF)

Of the four processes, MF uses a membrane with the most open structure, enabling dissolved material to pass through but rejecting most non-dissolved substances. MF helps to separate and reduce or remove fat, pathogens, and spores from the milk as part of a low-pressure process.

Ultrafiltration (UF)

UF utilizes medium pressure and a membrane with a moderately open structure, which allows most dissolved materials, such as lactose, salts, acids, and some non-dissolved components, to flow through it but rejects larger components. Ultrafiltration in the dairy industry retains fat and protein, allowing for the concentration of whey and milk proteins.

Reverse Osmosis (RO)

RO uses high pressure and a highly dense membrane that allows only water to cross through it, concentrating solids and rejecting dissolved and suspended materials. The pressure, temperature, pH, and feed stream quality, flow rate, and concentration all impact the effectiveness of this technique

Nanofiltration (NF)

As a medium- to high-pressure process, NF separates minerals from the milk by allowing only the liquid and certain monovalent ions to breach the membrane while withholding the majority of divalent ions. NF can be thought of as another form of RO, but with a membrane structure that’s a bit more open.

Applications

Each of these four processes has specific applications for dairy operations, as follows:

- Application of microfiltration in the dairy industry. The dairy industry uses MF for bacteria and fat reduction, milk protein fractionation and casein standardization, and cheese brine sanitation. MF helps improve the quality of milk, whey powder, and high-value dairy ingredients to produce extended shelf life (ESL) milk, cheese milk, and lactose-reduced or lactose-free milk.

- Application of ultrafiltration in the dairy industry. UF assists dairy filtration tasks with protein concentration and protein standardization, and boosts the yield of white cheese and fermented products.

- Application of reverse osmosis in the dairy industry. RO allows the dairy industry to efficiently reclaim water from the milk or whey before the evaporation stage, increase total solid content through solids recovery, or reduce the volume of milk or whey. RO is also beneficial for its sustainability, given its capabilities for waste recovery.

- Application of nanofiltration in the dairy industry. NF has specific uses in the dairy industry, such as reducing the mineral content and volume of whey and permeate, concentrating lactose prior to crystallization or evaporation, and producing quality lactose-free milk products.

Trust Membrane System Specialists, Inc. for Milk Separation Systems

As a leading provider of custom-designed membrane filtration systems for customers in the dairy industry and more, Membrane System Specialists focuses on exceptional quality, high-performance operational reliability, and energy efficiency. We offer design, system engineering, fabrication, and automation as part of our core services, along with sanitary installation, control and process integration, project management, and even operator training to best serve you with comprehensive, customized solutions. Contact us to learn how we support the food and dairy sectors with filtration systems and process equipment that meet the industries’ strict requirements, or request a quote today.