Understanding the Role of Crossflow in Membrane System Design

Comments Off on Understanding the Role of Crossflow in Membrane System DesignWhen it comes to designing membrane systems, one crucial aspect to consider is the filtration process. Crossflow filtration, also known as tangential flow filtration, stands out due to its unique feature. In this process, the feed solution flows parallel to the membrane surface, making it highly effective in applications that require continuous filtration and high efficiency.

This blog explores the benefits and applications of crossflow filtration, how it compares to dead-end filtration, and tips for designing it into membrane systems.

Benefits of Crossflow Filtration

Crossflow filtration is a preferred choice in many industries due to its numerous advantages, including:

Enhanced Membrane Longevity

Crossflow filtration reduces the rate of fouling by continuously removing contaminants from the membrane surface. This leads to fewer maintenance requirements and extended operational periods.

Improved Filtration Efficiency

This process maintains a steady flow rate and pressure across the membrane surface, resulting in consistent and reliable filtration performance. Its unique tangential design also allows for higher product recovery rates, selective filtration, and optimized process control.

Reduced Operating Costs

Implementing crossflow filtration can lead to significant cost savings. The extended membrane life and reduced maintenance requirements lower overall operating expenses. Additionally, the process requires less frequent cleaning, reducing downtime and labor costs.

Applications of Crossflow Filtration

Crossflow filtration is employed in various industries due to its efficiency and reliability. Some common applications include:

- Water treatment: This method is widely used to remove suspended solids, bacteria, and other contaminants in water and wastewater facilities, ensuring that the water meets stringent regulatory standards.

- Food and beverage processing: Crossflow filtration is used in this industry to clarify juices, concentrate proteins, and sterilize liquids.

- Pharmaceutical and biotechnology: This process concentrates and purifies biomolecules. It ensures the removal of unwanted particles while preserving the integrity of the valuable product, producing high-purity compounds.

Dead-End vs. Crossflow Filtration

Two primary techniques commonly used for membrane filtration are dead-end filtration and crossflow filtration. While both methods aim to separate contaminants from a fluid stream, they employ distinct mechanisms and offer unique advantages.

In dead-end filtration, the feed solution flows perpendicularly to the membrane surface. The entire feed is forced through the membrane, accumulating particles on the surface. This method is simpler and often used in low-contaminant applications. However, it can lead to rapid membrane fouling and requires frequent cleaning or replacement.

In contrast, crossflow filtration allows the feed to flow parallel to the membrane surface. Only a portion of the feed passes through the membrane, while the rest continues to flow along the membrane, carrying away larger particles. This reduces fouling and allows for continuous operation, making it suitable for processes requiring high efficiency and minimal downtime.

Tips for Designing Membrane Systems With Crossflow Filtration

Designing membrane systems with crossflow filtration requires careful consideration for optimal performance and longevity. Here are some essential tips:

- Choose the right membrane. Select membranes based on material, pore size, and chemical compatibility to suit your specific application needs.

- Optimize the system configuration. Set up flow rates, pressure settings, and membrane surface area for maximum efficiency and consistent performance.

- Implement regular maintenance. Establish a routine schedule for cleaning and inspecting membranes to prevent fouling and extend the system’s lifespan.

- Monitor its performance. Regularly monitor system performance to identify any issues early and take corrective action promptly.

- Seek expert advice. Consult membrane system specialists for guidance on selecting components and optimizing system design for your requirements.

Partner With Membrane System Specialists, Inc. For Custom Filtration Solutions

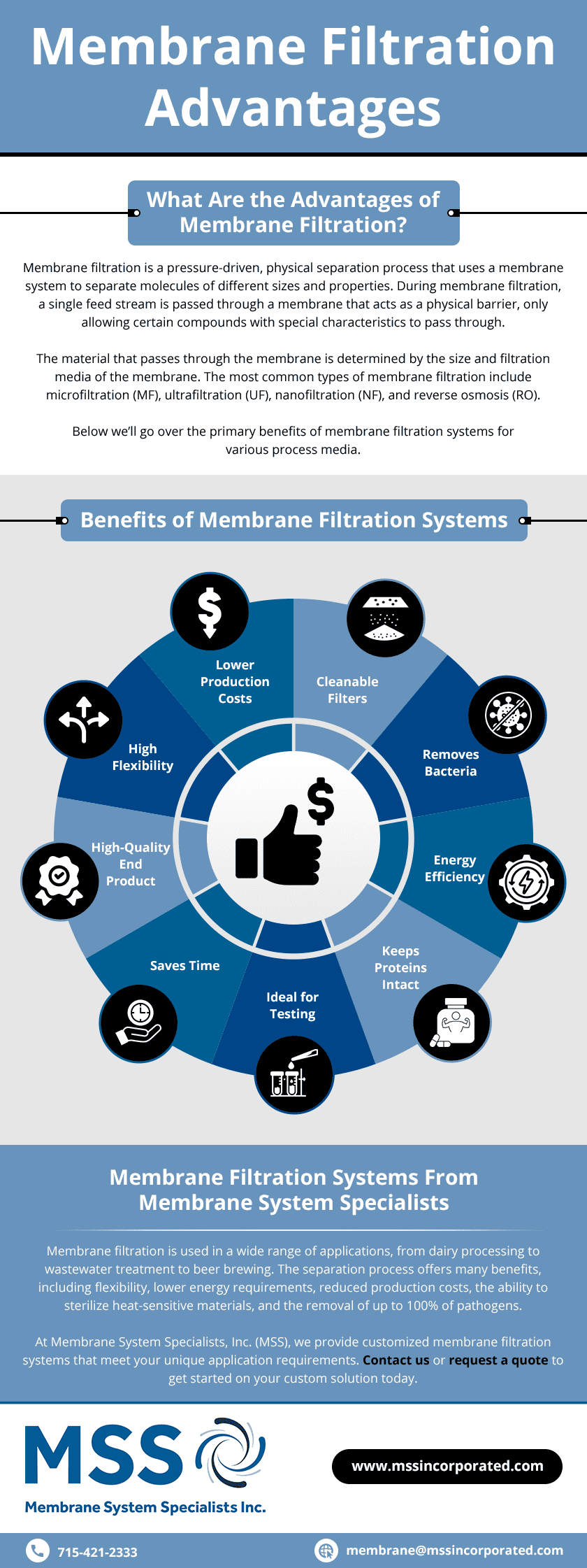

Membrane System Specialist Inc. is committed to providing advanced membrane solutions tailored to your needs! We offer comprehensive solutions for custom-designed, skid-built processing systems, including membrane filtration (UF, RO, NF, MF), pasteurization (HTST), CIP systems, and process integration. Our team also offers installation, commissioning, training, and full support throughout the equipment’s lifecycle, ensuring your systems maintain maximum separation efficiency.

Contact us and get started on your custom design today!