Membrane filtration is a pressure-driven, physical separation process that uses a membrane system to separate molecules of different sizes and properties. During membrane filtration, a single feed stream is passed through a membrane that acts as a physical barrier, only allowing certain compounds with special characteristics to pass through.

The material that passes through the membrane is determined by the size and filtration media of the membrane. The most common types of membrane filtration include microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO).

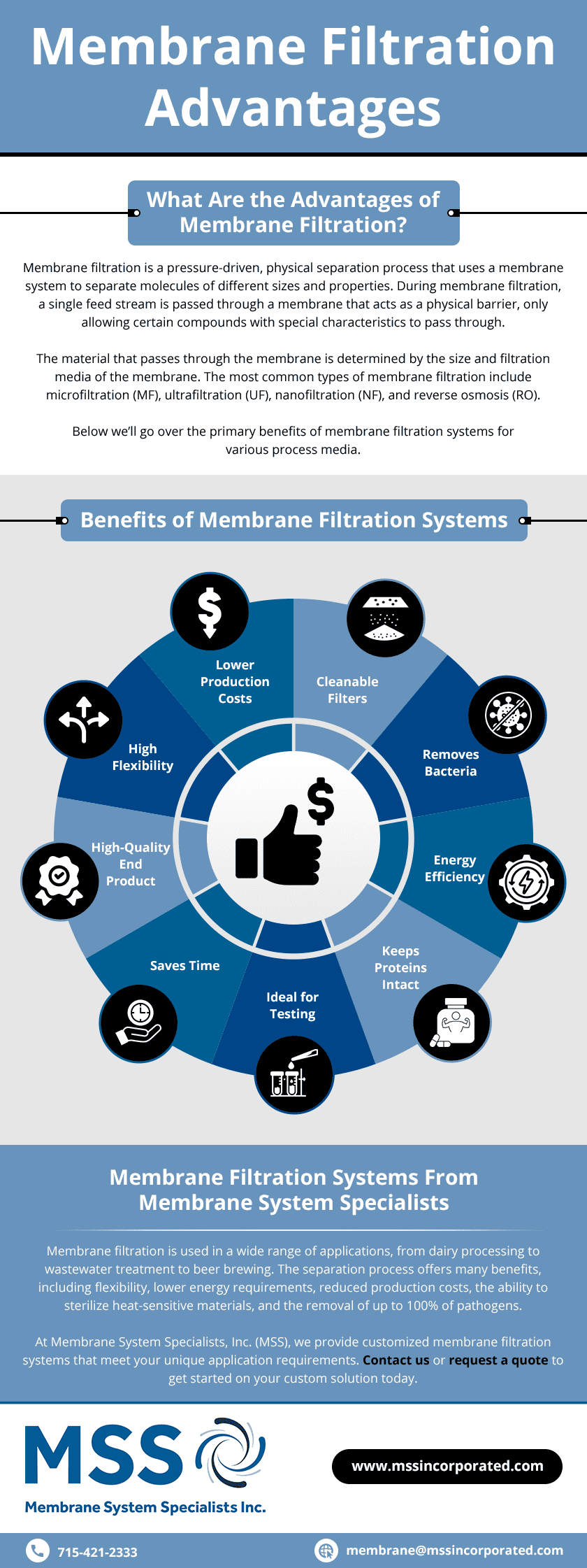

Below we’ll go over the primary benefits of membrane filtration systems for various process media.

Benefits of Membrane Filtration Systems

- High flexibility: Membrane filtration has a wide range of applications, from removing large particulate material to removing dissolved compounds. This means that no matter your separation challenge or application needs, different membrane filtration products are available to address them.

- Lower production costs: Unlike other technologies, membrane filtration is usually less expensive. This is because of its lower installation costs, lower energy costs, and fewer processing steps. At the same time, it produces a greater degree of purity and higher overall yields. Membrane filters don’t result in a filter cake, effectively eliminating costs due to residue disposal.

- No need for chemicals: To address the demand for limiting chemical concentrations used in water treatment, membrane filtration is an optimal solution because it doesn’t require any chemical additives. Instead, membrane filtration physically removes pathogens and eliminates the need to add chemicals, such as in chlorination.

- Removes pathogens: Membrane filtration can remove 90% to 100% of pathogens from the process fluid.

- Energy efficiency: Membrane filtration has considerably low energy requirements. For example, using ultrafiltration before nanofiltration and reverse osmosis saves energy by 20%.

- Keeps proteins intact: Membrane filtration is one of the most effective methods of separating proteins without denaturing them. Because it does not introduce chemical reagents or heat input, membrane filtration preserves the integrity of proteins.

- Ideal for testing: Membrane filtration is an effective method of assessing fluid samples for various types of contamination. By transferring the membrane filter from one medium to another, it can isolate and enumerate various bacterial colonies.

- Saves time: When obtaining quantitative data, membrane filtration provides quicker results than the MPN (most probable number) method. It only takes 24 hours for membrane filtration to yield results.

- High-quality end product: Membrane filtration is a clean, green technology that offers reliable, relevant results. The separation process is based only on molecular size, eliminating the need for additives. This results in a high-quality end product, which more easily complies with the high standards of consumers and strict requirements of regulators.

Membrane Filtration Systems From Membrane System Specialists

Membrane filtration is used in a wide range of applications, from dairy processing to wastewater treatment to beer brewing. The separation process offers many benefits, including flexibility, lower energy requirements, reduced production costs, the ability to sterilize heat-sensitive materials, and the removal of up to 100% of pathogens.

At Membrane System Specialists, Inc. (MSS), we provide customized membrane filtration systems that meet your unique application requirements. Contact us or request a quote to get started on your custom solution today.

Comments are closed