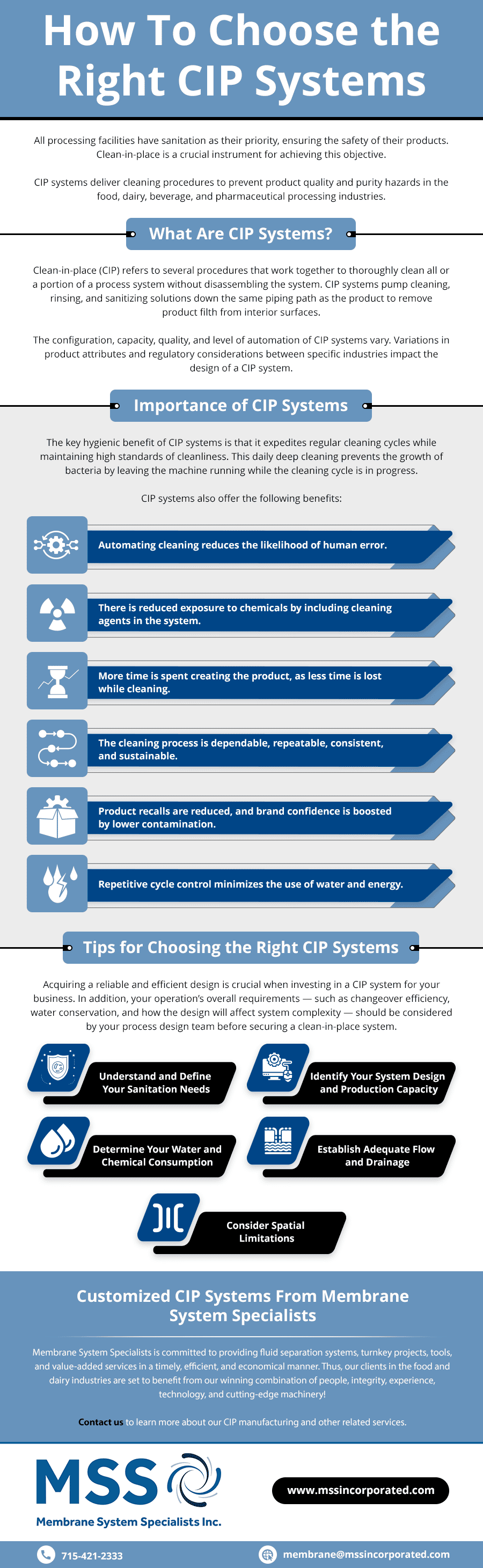

All processing facilities have sanitation as their priority, ensuring the safety of their products. Clean-in-place is a crucial instrument for achieving this objective.

CIP systems deliver cleaning procedures to prevent product quality and purity hazards in the food, dairy, beverage, and pharmaceutical processing industries.

What Are CIP Systems?

Clean-in-place (CIP) refers to several procedures that work together to thoroughly clean all or a portion of a process system without disassembling the system. CIP systems pump cleaning, rinsing, and sanitizing solutions down the same piping path as the product to remove product filth from interior surfaces.

The configuration, capacity, quality, and level of automation of CIP systems vary. Variations in product attributes and regulatory considerations between specific industries impact the design of a CIP system.

Importance of CIP Systems

The key hygienic benefit of CIP systems is that it expedites regular cleaning cycles while maintaining high standards of cleanliness. This daily deep cleaning prevents the growth of bacteria by leaving the machine running while the cleaning cycle is in progress.

CIP systems also offer the following benefits:

- Automating cleaning reduces the likelihood of human error.

- There is reduced exposure to chemicals by including cleaning agents in the system.

- More time is spent creating the product, as less time is lost while cleaning.

- The cleaning process is dependable, repeatable, consistent, and sustainable.

- Product recalls are reduced, and brand confidence is boosted by lower contamination.

- Repetitive cycle control minimizes the use of water and energy.

Tips for Choosing the Right CIP Systems

Acquiring a reliable and efficient design is crucial when investing in a CIP system for your business. In addition, your operation’s overall requirements — such as changeover efficiency, water conservation, and how the design will affect system complexity — should be considered by your process design team before securing a clean-in-place system.

Here are other tips to remember:

Understand and Define Your Sanitation Needs

How often does your production process require cleaning, and what materials are most susceptible to dirt accumulation and contamination? Identifying what you need helps you arrive at the ideal CIP machinery.

Identify Your System Design and Production Capacity

Knowing the size of the demand these cleaning systems need to satisfy and the industry’s production schedule is crucial. For instance, a single CIP tank system may be ideal for a small-scale company but may not be cost-effective for a regional producer.

Determine Your Water and Chemical Consumption

Water and chemical use are part of the production cost of a product. Newer CIP methods can help increase product yield while reducing rinsing time and water usage. Adding a recovery tank may also help conserve water, which is only possible with the right CIP system integrated into your cleaning routine.

Establish Adequate Flow and Drainage

Before choosing a CIP machine for your production needs, you must establish turbulence lines onsite. These lines improve the cleaning action of the fluid system without the need for high-speed flows. In addition, flooding and water spraying from the machine can occur when drainage is inadequately sized.

Consider Spatial Limitations

Depending on the plant layout, one may be required to install a centralized CIP machine that feeds multiple locations or several smaller systems spread across the plant area. Current piping systems also influence which type and how many systems can be integrated into the production line. Additionally, careful CIP configuration in a production line can lead to higher capital cost savings.

Customized CIP Systems From Membrane System Specialists

Membrane System Specialists is committed to providing fluid separation systems, turnkey projects, tools, and value-added services in a timely, efficient, and economical manner. Thus, our clients in the food and dairy industries are set to benefit from our winning combination of people, integrity, experience, technology, and cutting-edge machinery!

Contact us to learn more about our CIP manufacturing and other related services.

Comments are closed