What Is Liquid Nanofiltration?

Nanofiltration (NF) utilizes semipermeable membranes to filter our elements larger than 0.001 micron to 0.01 micron from a liquid feed stream. While the exact size of the elements filtered out depends on the size of the membrane pores, NF membrane filters can typically be used to remove suspended solids, microorganisms, and multivalent ions. Typical materials removed include:

- Antibiotics

- Dissolved organics

- Herbicides

- Insecticides/pesticides

- Latex emulsions

- Metal ions

- Nitrates

- Soluble salts

- Sugars

Compared to other liquid filtration methods, nanofiltration falls between reverse osmosis and ultrafiltration. Reverse osmosis has smaller membrane pores (less than 0.001 micron) and uses higher feed pressures to push the fluid through the membrane, while ultrafiltration has larger membrane pores (0.01 micron) and uses lower feed pressures. Its unique characteristics make it suitable for a variety of industrial applications. Below, we highlight some of its key industrial uses.

Applications for Liquid Nanofiltration

Nanofiltration is used in a wide range of liquid handling and processing operations. Some of the industries that regularly rely on it include:

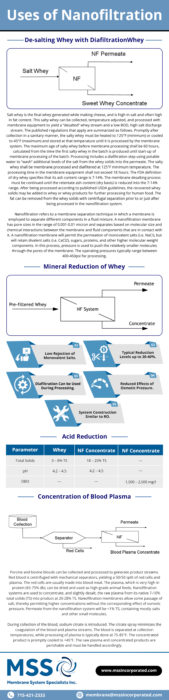

Dairy

In the dairy industry, nanofiltration is commonly utilized for whey concentration and other whey treatments. For example, cheesemakers use it to separate salt whey into low-salt and high-salt streams. It is also employed following clean-in-place operations to recycle cleaning solutions.

Food and Beverage

In the food and beverage industry, nanofiltration is used to separate various food materials into high-concentration and low-concentration streams. Besides dairy products, typical food and beverage components processed using this filtration method include beer, wine, coffee, and maple syrup.

Textiles and Dyes

In the textiles and dyes industry, nanofiltration is employed for many textile manufacturing operations. For example, it is used to desalinate and concentrate dyes for greater potency, recover fluorescent dyes after penetrant testing, and reconcentrate optical brightening agents to reduce operating costs.

Biotech and Pharmaceuticals

In the biotechnology and pharmaceutical industries, two of the main uses of nanofiltration are antibiotics production and blood processing. In antibiotics production, the filtration process is used to separate and concentrate antibiotics. In blood processing, it is used to desalinate, separate, and concentrate plasma and serum.

Wastewater Management

In the wastewater management industry, nanofiltration plays a key role in ensuring wastewater is safe for reuse or disposal. The filtration process is used to remove natural organic matter, suspended particulates, and other contaminants that may be harmful to humans or the environment.

Other Industrial Processes

The above list of applications is not all-inclusive. Nanofiltration is vital to many other industries and operations. For example:

- Brine salt purification and recovery

- Chemical recovery

- Drinking water softening

- Landfill leachate treatment

- Seawater sulfate removal

Liquid Nanofiltration Solutions From Membrane System Specialists

Nanofiltration is a low-energy, high-efficiency separation process, which makes it ideal for use in many industrial applications. If you’re looking for a system for your facility, turn to the experts at Membrane System Specialists! We’ve designed and manufactured custom, skid-built processing systems, including membrane filtration systems, for customers in the food and dairy industries for many years. To learn more about our system capabilities, contact us today. To discuss your system specs with one of our team members, request a quote.

Comments are closed