Our engineers at Membrane System Specialists, Inc. design, produce, and fit various custom fluid processing equipment used in dairy and other food processing applications. With our skill and expertise, we can provide complete processing systems and turnkey solutions for our clients.

Our engineers can customize membrane filtration equipment systems to meet all our customers’ needs. All equipment is custom-sized and based on proven designs that have been used in the industry for over 30 years.

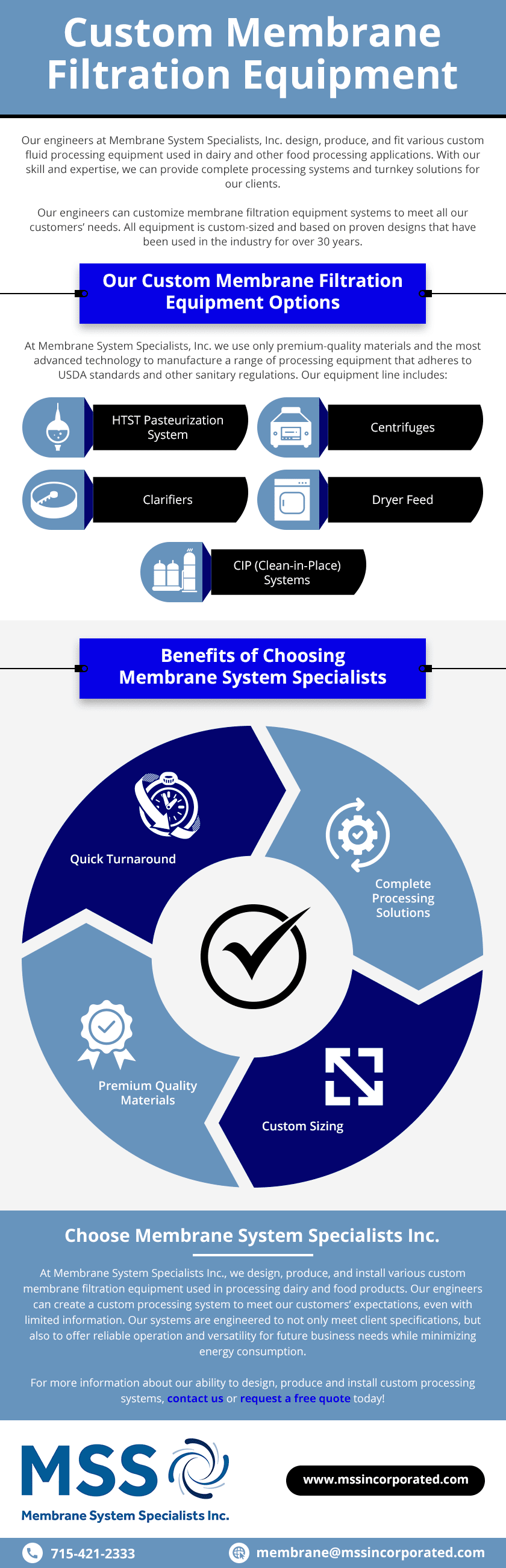

Our Custom Membrane Filtration Equipment Options

At Membrane System Specialists, Inc. we use only premium-quality materials and the most advanced technology to manufacture a range of processing equipment that adheres to USDA standards and other sanitary regulations. Our equipment line includes:

HTST Pasteurization System

HTST pasteurization systems use a continuous pasteurization process. A plate or tubular heat exchanger heats the products. The plate heat exchanger passes the product via a frame of stainless steel plates clamped together, typically using hot water as a heat source. Tubular heat exchangers are usually used to heat products containing elements that can block the channels of a plate heat exchanger.

Centrifuges

Centrifuges and production processes enable industry-scale production of dairy products such as quark, strained yogurt, and fresh cheese. Our centrifuges provide a cost-effective and efficient production method while ensuring pleasing texture and taste.

Clarifiers

Specialty clarifiers, separators, and other treatment processes can be designed to meet our clients’ specific needs and provide long-term service. We know that no two waste streams are the same, and, in most cases, require custom modifications. Some things to consider for a successful installation include flow patterns, sludge treatment, effluent requirements, tank sizing, and skimming methods.

Dryer Feed

Drying and particle processing plants are used to produce various products, from bulk products to extremely advanced powders within chemicals, pharmaceuticals, food, and dairy products. Plants of different sizes are available, ranging from small pilot plants for research and product development to huge industrial systems.

CIP (Clean-in-Place) Systems

Our CIP systems are engineered to meet your plant’s unique application, layout, and utility requirements for sanitary process equipment cleaning. Adequate flow is ensured by our application-specific CIP design and size. As a result, enough pressure is available to remove residue fully, rinse properly, reduce cycle times, and ensure workers are safe.

Benefits of Choosing Membrane System Specialists

- Complete processing solutions: Oftentimes, our customers contact us only knowing the product they want to make and the approximate composition and volume of available feedstock. From this, our engineers can make a custom system that fulfills their needs.

- Custom sizing: We custom-size all of the equipment we produce to meet the unique needs of each client and use a foundation of trusted designs that have proven successful for nearly 30 years.

- Premium quality materials: To meet the sanitation requirements of sensitive industries, such as food processing, we use only the highest quality materials.

- Quick turnaround: We strive to be at the forefront of new technologies and controls to create systems that allow processors to produce consistently and quickly, reducing the need for downtime due to maintenance. The time it takes to make custom equipment varies depending on the scale of the job, but it usually takes between 8 to 16 weeks.

Choose Membrane System Specialists Inc.

At Membrane System Specialists Inc., we design, produce, and install various custom membrane filtration equipment used in processing dairy and food products. Our engineers can create a custom processing system to meet our customers’ expectations, even with limited information. Our systems are engineered to not only meet client specifications, but also to offer reliable operation and versatility for future business needs while minimizing energy consumption.

For more information about our ability to design, produce and install custom processing systems, contact us or request a free quote today!